Item Control Setup Guide

From Adjutant Wiki

Contents

- 1 Overview

- 2 Initial Setup

- 3 Review and Update Rule Maintenance Records

- 3.1 Item Attributes (ITEMATTRIB)

- 3.2 Item Commodity Codes (FOB)

- 3.3 Item Price Group Codes (ITEMGRP)

- 3.4 Item Transaction Categories (ITEMCAT)

- 3.5 Departments (DEPT)

- 3.6 Units of Measure (UNITS)

- 3.7 Inventory vs GL Dump Accounts (INVDUMP)

- 3.8 GL Accts for Inventory (INVGLACCTS)

- 3.9 Freight Terms (FREIGHT)

- 3.10 Ship Via Codes (SHIPVIA)

- 3.11 Sales Order Bullet Notes (SOBLIST)

- 3.12 Sales Order Certs Defaults (SOCERTS)

- 3.13 Sales Order Date Defaults (SODATES)

- 3.14 Sales Order Freight Charge (SOFRTCHARGE)

- 3.15 Sales Order PDF Attachments (SOPDF)

- 3.16 Sales Order Priority (PRIORITY)

- 3.17 Sales Order Project Complete Check (STOPSOPROJCOMP)

- 3.18 Sales Order SOC Columns (SOCOLUMNS)

- 3.19 Sales Order Sort (SOSORT)

- 3.20 Sales Order Types (SOTYPE)

- 3.21 Sales Order Types (Overflow) (SOTYPE2)

- 3.22 Sales Order Use (SOUSE)

- 3.23 Customer Comment Codes (CUSTCOMM)

- 3.24 Quote Default Date Offsets (RFQDATE)

- 3.25 Quote Order Types (RFQTYPE)

- 3.26 Quote Sorting (RFQSORT)

- 3.27 Terms of Payment Codes (TERMS)

- 4 Optional

- 4.1 Set up ABC Controls

- 4.2 Set up Cycle Count Code Controls

- 4.3 Set up Search Code Controls

- 4.4 Set up Misc Code Controls

- 4.5 Establish Salespersons and Account Managers

- 4.6 Set Default SO/RFQ Types by User

- 4.7 Sales Order Form(s)

- 4.8 Customer Pricing

- 4.9 Set the Next SO Number

- 4.10 Set the Next Quote Number

- 5 Review and Complete Additional Sales Order Setup

- 6 Scrub and Import Open Sales Order Data

Overview

This guide covers the setup of Item Control application.

The Item Control system covers the setup and maintenance of inventory item codes, including stock, non-stock, miscellaneous, and production items. Item Codes are used throughout Adjutant in most of the application areas. The Item Control system is deeply integrated with the Order Entry, Production, Shipping and Logistics, Purchase Order (PO), Asset Management, Accounts Receivable, Accounts Payable, Task Management, and Accounting applications. The Item Control application setup involves some steps that must be completed during the System Manager setup in order to proceed with further setup. The remaining Item Control setup steps should be completed prior to setting up the Purchase Order Setup Guide, the Order Entry and Quoting Setup Guide, and the Production Setup Guide to avoid running into any roadblocks.

A solid understanding of the client's inventory accounting model is required to accurately set up Item Warehouse and Owner/Heldfor records accurately.

Initial Setup

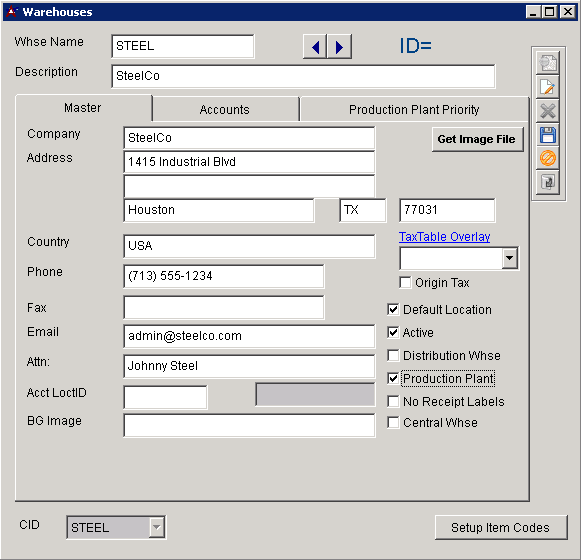

Verify/Create Warehouse Records

The default Warehouse and default Holder should be created during the initial CID setup process. Those steps are included in the System Manager Setup Guide and the MASTER CID Copy Guide.

Review the Warehouses screen and add any additional Warehouse locations. If the CID only requires a single Warehouse, review all tabs in the Warehouses screen and confirm the accounting setups and Warehouse flags are correct.

- The default Warehouse name should match the CID name. In most cases, the ‘Default Location’, ‘Active’, and ‘Production Plant’ checkboxes should be checked.

- The add process will create a new Organization with a ‘Warehouse Location’ attribute.

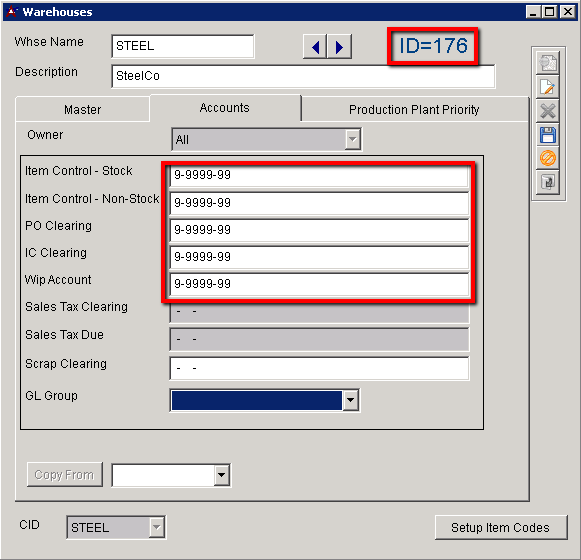

- You must complete the blank GL accounts in the ‘Account’ tab in order to save the record.

- If creating multiple 'Production Plant' Warehouses, review and update the Production Plant Priority tab as needed.

- Review the Sales Tax Calculations Wiki information on Tax Table Overlay logic to determine if an overlay is appropriate. It is generally only required for Texas warehouses.

- After a successful add, the 'ID=' value will display with the internal keyno for the Warehouse. This is the loctid value in many item-related data tables and will be important to note when dealing with multiple Warehouses.

Verify/Create Inventory Holder Records

- Review the ‘Item Held For Codes’ (HOLDER) Rule Maintenance record and verify that the default inventory holder (log1 is checked) is set up and marked as active (log2 is checked).

- Add any additional inventory holders as needed. Additional inventory holders are a rare setup.

Import the CID Items

The CID Items file contains all of the system default item codes required by the different applications. If the CID Items are not set up, several basic functions in Accounts Receivable, AP, Tasks, and Data Imports will not work.

- A copy of the ‘cid_items_new.xls’ file can be found in the \Data Files\Items folder of the Adjutant directory (if copied from MASTER), or a copy can be found in the Implementation Files folder on the FTP.

- Edit the file and update the HeldFor, WHSE, and OwnerID values so they match your environment. Save the file as a Microsoft Excel 5.0/95 Workbook.

- Import the file as-is using the ‘Import Item Master’ screen. No special attributes are needed.

Set up BIN Controls

At a minimum, verify that the 'PUTAWAY' bin has been created. There are several areas where Adjutant relies on a PUTAWAY bin to complete certain transactions. If the PUTAWAY bin was not copied/created during the CID setup process, add the PUTAWAY bin in the Bin Control screen and flag it as 'ACtive' and to 'Allow Multiple Items'.

Controlling inventory location with bins is an advanced setup, and not all customers will need the additional control and maintenance of bins. If the customer will be using bins to control inventory location, use the Bin Import template to create all the required bin names. Bins can also added one by one in the Bin Control screen.

Review and Update Rule Maintenance Records

Item Attributes (ITEMATTRIB)

Item Attributes can define item types, assign special reflexes or provide additional details about item codes. The MASTER CID is updated with the most common item attributes and their corresponding form/jump screen where appropriate. Review the Item Attributes rule and add any attributes that are needed.

- Most Item Attributes are hard-coded based on the 'Name' value in the rule, but the Description value can be customized.

- The 'Group' value controls how the item attribute list is displayed in the Item Master screen. Attributes with the same Group value will display together in alphabetical order.

- At a minimum, review and customize the Department attributes to match the customer's setup. The MASTER departments are examples, and will not work for all customers.

- The 'Name' value for department attributes should be the unique two-character department code that matches the code in the Departments (DEPT) rule

- The two-character department code should also be entered in the Dept Code (text8 ) field

- Production department items that require profile details (such as panel and purlin) should have the 'PROFILE' form associated with the department attribute

Item Commodity Codes (FOB)

Commodity Codes are designed for the procurement system to work with commodity groups and to generate vendor inquiries based on the code setups. Commodity Codes are also a filter on several Item Master reports and they can be used to create another layer of item grouping for inventory reporting.

Commodity Codes are an optional setup, but can be a useful filter or grouping option for standard and custom reports.

Review and update the Item Commodity Codes rule as needed. The MASTER codes are examples and will not work for all customers.

Item Price Group Codes (ITEMGRP)

Item Price Groups are used to define pricing tiers in the Customer Pricing screen. Item Price Groups should be aligned the customer's desired pricing scheme.

Review the Item Price Group rule and set up all needed price group codes. The MASTER codes are examples and will not work for all customers.

Item Transaction Categories (ITEMCAT)

Item Transaction Categories are used together with Customer Transaction Categories to define which Revenue and Cost accounts are used for different transaction types. Item Categories are defined in the rule, and tied to individual item records in the Item Master Settings tab, or the Item Master OHF record. The Item Category in the OHF record overrides the entry in the Item Master Setting tab.

An Item Category code of 'DEF' should exist for all customers. Set up any additional categories needed based on the customer's revenue and cost accounts that should be hit for certain items. Review the [Journal Entry Architecture] wiki for additional information on how GL Groups can affect the default accounting setups.

The MASTER codes are examples and will not work for all customers.

http://www.abiscorp.com/adjwiki/rule-itemcat.ashx

Departments (DEPT)

Department codes are used in several other applications in addition to Item Control. Their primary function in Item Control is to route production work orders and control profile information for certain item types. Departments can also be used to sort and group items on certain reports.

For Item Control, the two-character department code must match the 'Name' and the 'Dept Code' values for the related department attribute in the ITEMATTRIB rule.

Review the Departments rule and set up all needed departments based on the customer's production routing and inventory grouping needs. The MASTER codes are examples and will not work for all customers.

Units of Measure (UNITS)

The Units of Measure rule is a large and powerful rule that control item unit conversions between different unit types. The rule uses two factors to calculate the equivalent units for different unit measurements.

- For each defined base unit, a 1:1 entry should be created. For example, Each to Each should have a Factor 1 of '1.00' and a Factor2 of '1.00'

- The 'Group' value controls the available Unit Group entries in the Item Master screen and helps organize details in the rule

- The 'Group' value can also define different 'Name' to 'Base Unit' conversions based on the unique 'Group' name

- Factor1 defines how many unit names are equivalent to a single base unit. For example, if DAY is the unit name and HOUR is the base unit, Facor1 would be 1/24th or .041666. You would have to divide a day by 24 to get a single hour, or 1 hour is 1/24th of a day.

- Factor2 defines how many base units are equiavlent to a single unit name. For example, if DAY is the unit name and HOUR is the base unit, Factor2 would be 24.000. You would have to multiply hours by 24 to get a single day, or 1 day is equivalent to 24 hours.

The MASTER rule has a large default set of units, and is updated occasionally with common units. Review the Units of Measure rule and add any units needed for your customer. If you add unit entries that may be useful for other customers, send the details to the MASTER CID Administrator to include in the MASTER rule.

http://www.abiscorp.com/AdjWiki/Units%20of%20Measure.ashx

Inventory vs GL Dump Accounts (INVDUMP)

GL Accts for Inventory (INVGLACCTS)

Freight Terms (FREIGHT)

Freight terms are valid in Order Entry, Shipping, and Purchase Orders. Add any needed freight types to this rule to populate the list of available freight types in the associated applications.

Ship Via Codes (SHIPVIA)

The SHIPVIA rule sets the valid drop-down entries for the Ship Via field in the Order Entry, Purchase Order, and Shipping Events applications. The rule also controls several alerts and automated reflexes, like generating shipping events, or adding certain charges.

Review this rule carefully for any special options and reflexes. Add any needed ship via methods to the rule.

Sales Order Bullet Notes (SOBLIST)

Sales Order Bullet Notes are an optional feature where users can select pre-defined verbiage (saved in a text file) for printing in a custom area on Quote or Sales Order forms. The short and long descriptions are displayed for selection on the Quote or Sales Order Header screen by selecting the 'SOb' button. The 'SOb' button only shows up if the rule has been set up.

Sales Order Certs Defaults (SOCERTS)

The SOCERTS rule controls when the 'Certs' box is checked on the Sales Order Header screen. Define up to 5 item department codes that must be matched in order to automatically select the 'Certs' box. If multiple department codes are set up, items matching ALL defined department codes must be sold on the order before the 'Certs' box will be checked.

The 'Certs' box can be used as a print when on forms to drive custom procedures or requirements.

Sales Order Date Defaults (SODATES)

The SODATES rule controls how the SO Load Date, SO Required Date and the PWO Due Date set on a new SO. The rule allows you to override the default logic using offset days from the SO Date when creating new SOs. Verify the entries in this rule are what the client wants.

Sales Order Freight Charge (SOFRTCHARGE)

Works with CID Setup Option SOFRTCHARGE to define custom freight charges based on the matched freight item code. Custom calculations can be defined per freight item to determine a freight price based on the total weight or total feet on the order.

Sales Order PDF Attachments (SOPDF)

The SOPDF rule is similar in concept to the SOBLIST rule. PDF files can be stored on the Adjutant server and tied to a specific item code or a specific payment term name. When a match is made, the linked document will automatically be included as a linked document on the Sales Order or Quote. Setting up the rule also adds a 'PDF' button where users can manually select the PDF document(s) to link to an order or quote.

Sales Order Priority (PRIORITY)

The PRIORITY rule controls the available options in the Priority drop-down field on the Sales Order Header.

Sales Order Project Complete Check (STOPSOPROJCOMP)

If a SO Type code is listed, and a sales order is added that matches the code, the user will be prevented from saving the order if the linked Project record is completed.

Sales Order SOC Columns (SOCOLUMNS)

The SOCOLUMNS rule defines which values from SOC report codes will show up as columns in the Line Item Entry and Line Item View grids in Quotes or Sales Orders.

Sales Order Sort (SOSORT)

Custom sort methods can be defined based on SO Type for the Sales Order Confirmation form or the SO Packing List form.

Sales Order Types (SOTYPE)

The SOTYPE rule controls many key behaviors, features, and functions for Order Entry. Create each required SO Type for the customer and carefully review each type for appropriate options and settings. The most common fields to review for this rule include:

- SO Type Name, Code , Default flag, and custom Prefix

- Default SO Form and default Invoice form

- GL Group

- Change Order indicator (an entry of 1 defines that SO Type as a Change Order)

- Suppress Shipping Event

- Allocate defines whether or not item quantities are considered allocated when sold as a line item

Sales Order Types (Overflow) (SOTYPE2)

The SOTYPE2 rule is a continuation of the SOTYPE rule because all available rule fields had been used on the SOTYPE rule. Additional features like the AR GL Account override and the Zero Prices feature are set up here. The SO Type Code links the additional features to the SO Type Code in the main SOTYPE rule.

Sales Order Use (SOUSE)

The SOUSE rule controls the options available in the Use drop-down field in Sales Order Line Item Entry. The SO Use field was developed to drive additional print options on the SO Form for the chemical industries, but can be used for any custom need.

Customer Comment Codes (CUSTCOMM)

Customer Comment Codes are pre-defined short notes that can be selected for printing on forms from the Comment drop-down on the Quote or Sales Order Header screens. Comment Codes are shared between the Sales Order and the Invoice record and can be changed on the Invoice Master as well.

Quote Default Date Offsets (RFQDATE)

The RFQDATE rule works like the SODATES rule to define the default dates used for Quote Expire Date and Quote Required Date, by using offset days from the Quote Date.

Quote Order Types (RFQTYPE)

The RFQTYPE rule controls many key behaviors, features, and functions for Quoting. Create each required Quote Type for the customer and carefully review each type for appropriate options and settings. The most common fields to review for this rule include:

- RFQ Type Name, Code , Default flag, and custom Prefix

- Default Quote Form

- Whether a 'won' quote creates a new SO#, or uses the same RFQ#

Quote Sorting (RFQSORT)

Custom sort methods can be defined based on RFQ Type for the Quote Confirmation form.

Terms of Payment Codes (TERMS)

The TERMS rule controls the valid terms of payment for both the AR and AP applications. Reconcile the entries against the customer questionnaire and the Open AP Invoice import data (if customer's data includes payment terms). Add any needed terms and delete any terms that are not needed. Too many TERMS options generally add user confusion and can create invoice records with unwanted terms.

Optional

Set up ABC Controls

Set up Cycle Count Code Controls

Set up Search Code Controls

Set up Misc Code Controls

Establish Salespersons and Account Managers

Assign the 'ACCTMGR' attribute to all employee contact records that should appear in the Acc Mgr drop-down list.

Assign the 'SALES' attribute to all employee contact records that should appear in the Salesperson drop-down list.

It is common for clients to want to relabel the Account Manager and Salesperson roles to match their structure. At a minimum, update the following records:

- Rule Maintenance - Contact Attributes - SALES attribute description

- Rule Maintenance - Contact Attributes - ACCMGR attribute description

- Sales Order - Labels - lacctmang - Current Value (Should cover both SO and RFQ)

- Sales Order - Labels - lsp - Current Value (Should cover both SO and RFQ)

- ALL forms that display Salesperson or Account Manager labels will need to be customized

- ALL reports that the client uses that display Salesperson or Account Manager will need to be customized

Set Default SO/RFQ Types by User

If the client wants the default SO or RFQ type to be set per user, get a list of which users and which types should default from the client.

The SOTYPE-X attribute (where X represents the SO Type code) can be created and added to employee contacts to default the SO type for that user.

The RFQTYPE-X attribute (where X represents the RFQ Type code) can be created and added to employee contacts to default the RFQ type for that user.

Make certain that the -X matches the SO Type Code and RFQ Type Code defined in the corresponding SOTYPE and RFQTYPE rules.

Sales Order Form(s)

Work with the client to determine how many SO form layouts will be needed for their operations. SO forms are defaulted according to SO type in the SOTYPE rule.

If the customer has separate invoice forms for each SO type, the invoice form can be defaulted according to the SO type in the same SOTYPE rule.

- The default SO form from MASTER should only need minor customizations for disclaimer areas, and to confirm that the logo images scale and display correctly. Clients that have specific business needs for additional form customizations should understand that the forms were designed with best practices in mind for most customers. Additional customizations cost time and money and should only be requested if there is a clear business need for the changes.

- Make any further customizations required by the client and create additional forms as needed.

- Get client approval on all SO forms.

Customer Pricing

Customer pricing can be set up by the following combinations:

- Customer Price Code(Group) and Item Price Group

- Customer Price Code(Group) and Specific Item

- Specific Customer (Ent) and Item Price Group

- Specific Customer (Ent) and Specific Item

Set up all needed Customer Price Codes in the ENTGROUP rule.

Set up up all needed Item Price Groups in the ITEMGRP rule.

Use the Price Group Import utility to import large, custom pricing setups. If there are any errors, or mass changes needed after the import, the Customer Pricing data is help in the PRICEGROUP data table.

Set the Next SO Number

Review and update the 'Prefix' and 'Current Number' values in the CID Maintenance Counters tab for the SONO line. Establish the beginning SO number. The Prefix value can be overridden by a prefix defined in the SOTYPE rule.

Set the Next Quote Number

Review and update the 'Prefix' and 'Current Number' values in the CID Maintenance Counters tab for the RFQNO line. Establish the beginning Quote number. The Prefix value can be overridden by a prefix defined in the RFQTYPE rule.

Review and Complete Additional Sales Order Setup

Set up Templates and Recurring Orders

Discuss Sales Order Templates and Recurring Sales Orders with customer.

- Set up any templates and/or recurring orders as needed with the customer. Use the Recurring Order WIki as a reference for the recurrence codes.

Discuss Security Options Around Order Entry

Sales Order Entry has several security options that are open, or unlimited by default. Discuss any personnel security concerns around order entry or order management with the customer.

Below are some of the more common security options that customers should be aware of, and may need review:

- Open/Close - whether an employee can manually reopen or close an SO

- Hide Margin/List/Cost - Cost and overall margins are displayed in several spots on the Sales Order. Setting these options hides it in all screens.

- Delete Lines - whether an employee can delete previously added lines from an SO

- Change Terms - whether an employee can change the payment terms tied to an order.

Scrub and Import Open Sales Order Data

Open Sales Order conversions are rare, and generally discouraged. Generally, the amount of open sales orders for any client is small enough that it is not worth going through the scrub and import process. The value of having the end-user train on the Order Entry system by entering the open orders manually usually outweighs the amount they would spend on having ABIS complete a data import for a handful of records.

If the client requires an open sales order conversion, refer to the Sales Order Conversion Guide (UNDER CONSTRUCTION) for detailed information on the import and reconciliation process.