PWO Visual Scheduler

From Adjutant Wiki

General Information

Default Menu Location: Transaction >> Production >> PWO Visual Schedule

Screen Name: PWOVisualSchedule_s.htm

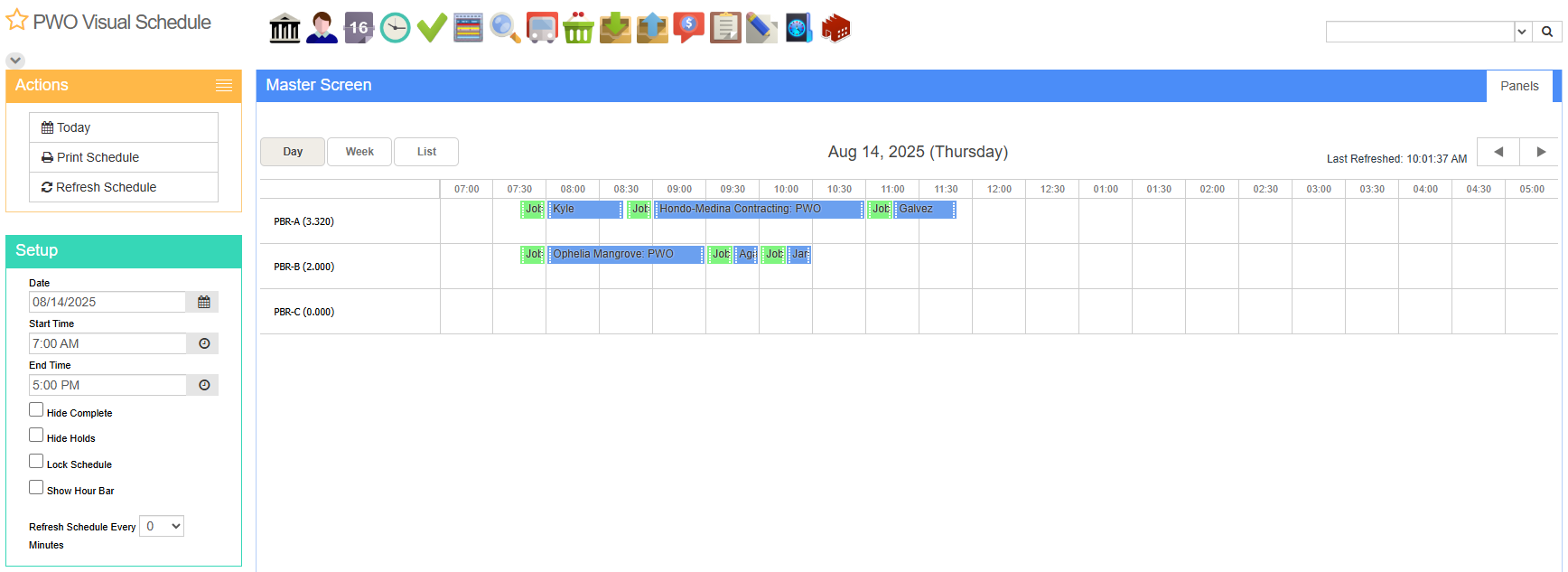

Function: The Production PWO Visual Schedule allows users to see their jobs in a calendar format and update the schedule times and even the machine that the job is assigned to run on. The schedule uses tasks to represent the machine production hours needed for each PWO.

When everything is set up, production work orders that are tied to specific machines will automatically generate task records that can be moved around on the schedule to adjust the scheduled time or machine.

Setup Required

The PWO Visual Schedule requires a few areas of setup to support the feature. Some of these areas of setup may require assistance from ABIS Support personnel. It is highly encouraged to work with an ABIS Support representative for assistance with changes to Rule Maintenance settings and CID Setup Options.

In order for the PWO Visual Schedule feature to work, the following setup items must be completed:

- CID Setup Option MULTIMACHINE must be enabled, and all production items should have a Machine defined in their department profile attribute. The machine value is the link to the Asset and Resource records.

- A single default Standard Task record named PWOGEN must be created.

- The Profile Machine (PMACHINE) Rule Maintenance record must be updated with scheduling controls for each machine that should show on the PWO Visual Schedule.

- New custom Schedule Tabs must be defined and set up in the Schedule Tab Names (TABS) Rule Maintenance record for the new PWO Schedule.

- An Asset record must be created for each machine.

- A Resource record that matches the machine name must be created on the Asset record.

Enable MULTIMACHINE

The CID Setup Option MULTIMACHINE is required to allow creating PWO records using the combination of Department and Profile Machine. If this option is not already enabled in your environment, contact ABIS Support to discuss enabling the option. There may be database-level changes required for any saved machine names that may require ABIS support to address.

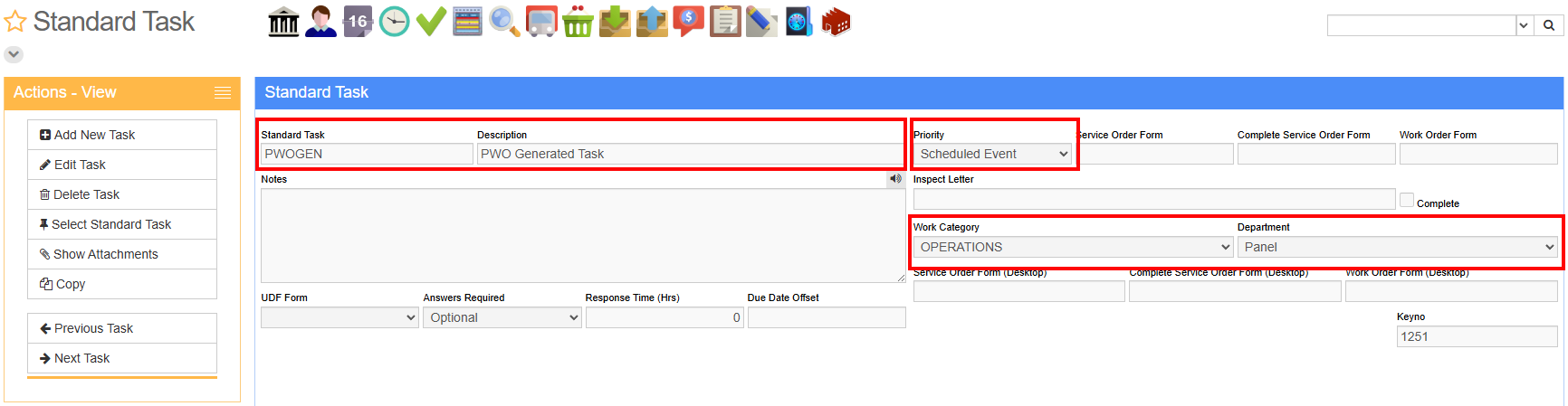

Create PWOGEN Standard Task

Create a standard task with the following details:

- Standard Task: Must be PWOGEN

- Description: Can be anything, but PWO Generated Task is suggested

- Priority: Select any valid priority code from the drop-down list to assign the default priority for all PWOGEN tasks. This list of priority codes will be unique for each customer.

- Work Category: Select an appropriate category to use for all PWOGEN tasks. This list of work category codes will be unique for each customer.

- Department: Select an appropriate department to use for all PWOGEN tasks. This list of work department codes will be unique for each customer.

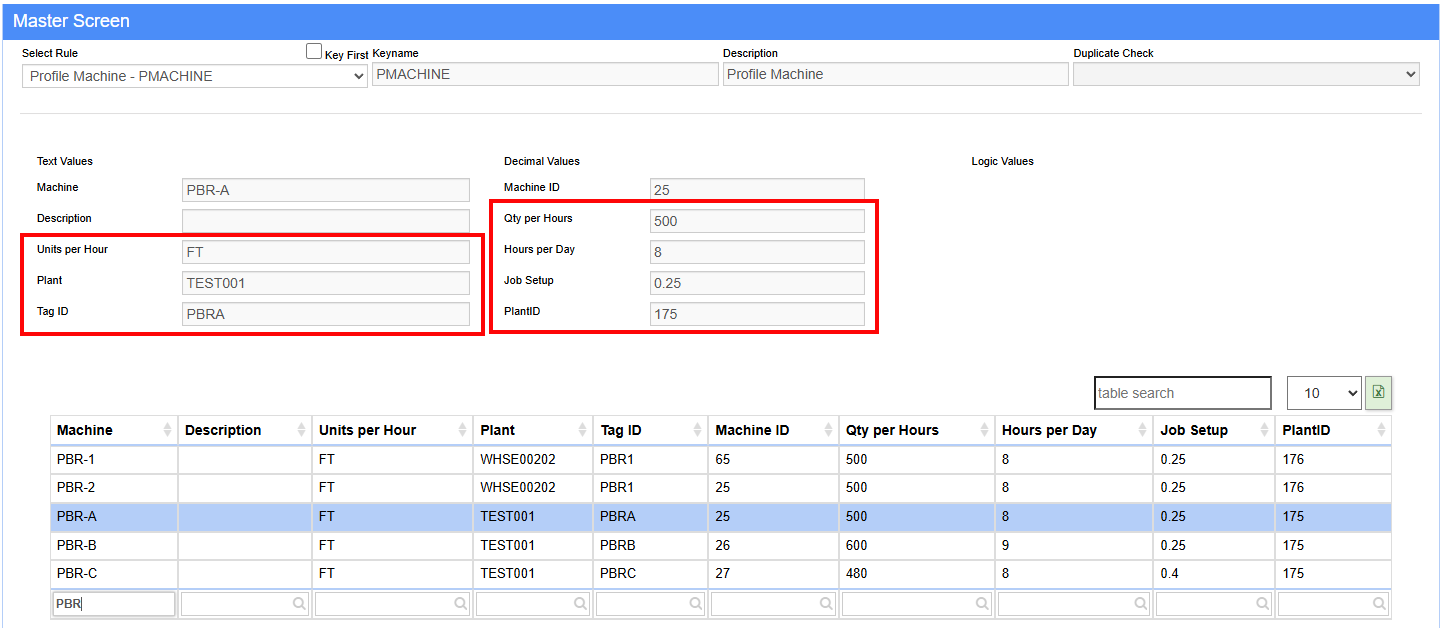

Set up PMACHINE Rule Maintenance

Above is an example PMACHINE Rule Maintenance setup for a few PBR Panel machines. Configure each machine that you want to use with PWO Visual Scheduler. Below are fields related to the PWO Visual Schedule setup. If this Rule Maintenance record needs the newer fields added, it is highly recommended to contact ABIS Support for assistance. Updating Rule Maintenance records incorrectly can lead to destroyed data and can cause certain features/systems to stop functioning.

- Units per Hour (text3): Enter the unit of measure (i.e. FT, LBS, EA) that will be used for tracking the machine's production capacity.

- Plant (tex4): This should match the Production Plant name.

- Tag ID (text5): This value must exactly match the Asset record Tag ID value for the machine Asset record in the next step. Best practice is to match the Asset Tag ID and the machine name.

- Qty per Hour (num2): Enter the Qty (in the same unit as Units per Hr) for the machine's capacity in an hour.

- Hours per day (num3): Enter the number of hours available for that machine in a day.

- Job Setup (num4): Enter any time that should be added to each job for machine setup, expressed as fractions of an hour.

- Plant ID (num5): Enter the LoctID value for the Production Plant

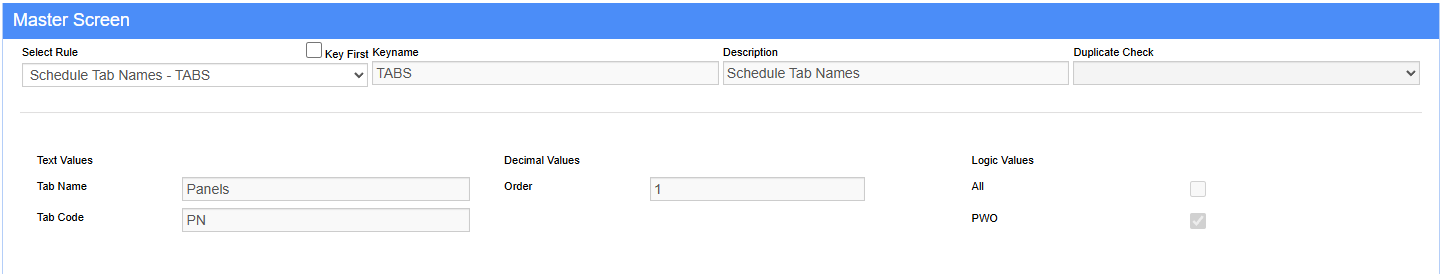

Customize Schedule Tabs as Needed

Add any new Schedule tabs that are needed in the Schedule Tab Names (TABS) Rule Maintenance record and check the 'PWO' box. Note that the new logic2 field labeled 'PWO' is required to designate a tab name for the PWO Visual Schedule. If the rule record does not have the 'PWO' logic field, work with ABIS Support to get it added.

Create an Asset Record for each Machine

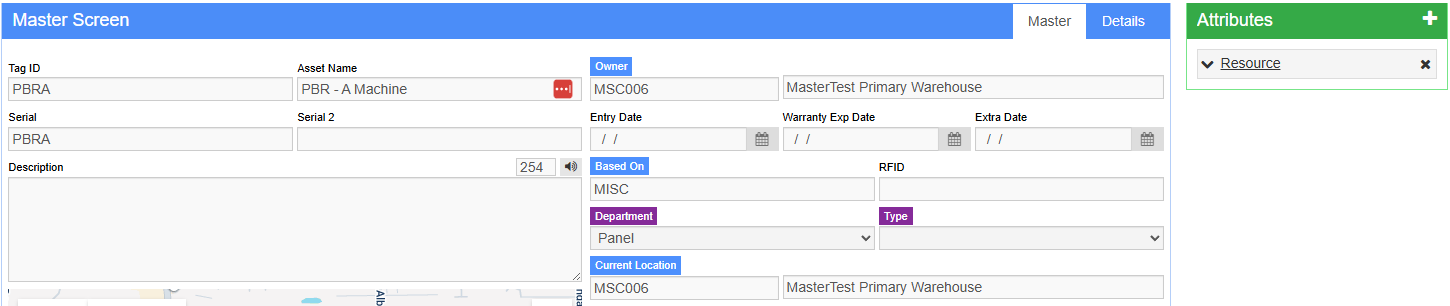

Each machine that will be used with visual scheduling must be added as an Asset record with the Asset Tag ID matching the Profile Machine rule value. The Owner and Current Location are generally set to your primary Organization ID. The Based On value requires an Item Master item code - generally a MISC item is appropriate.

Note the Resource Attribute is attached to the Asset record on this screen.

Create a Resource Record for each Machine Asset

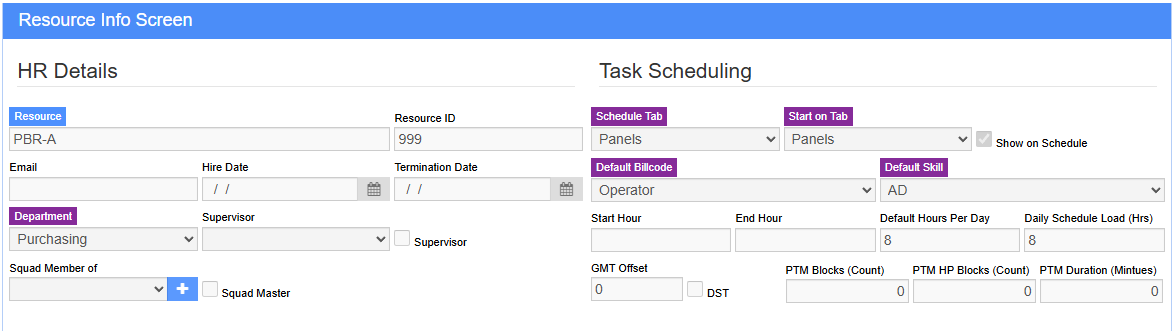

On each Asset record, a Resource record must be created. IMPORTANT Make sure the Resource name value matches the machine name from the PMACHINE rule. The logic is hard-coded to assume the resource matches the machine name. Select the desired Schedule Tab name (from the TABS rule) where the machine resource should show on the schedule. The remaining required fields can be completed with whatever defaults make the most sense.

Once all of the above pieces are in place, when a user submits a work order to the plant, the system will generate a task record linked to that PWO that is represented on a custom schedule screen according to it's PWO Schedule Date and expected duration based on the machine's capacity settings.