Bin Import Guide

From Adjutant Wiki

Contents

General Import Template File Notes

- Template files are typically generated from their respective Import screen using an 'Export Template' button.

- Using the 'Export Template' button from an updated system will help ensure that you are using the most up-to-date import file, and will help avoid errors.

- Templates generally (but not in all cases) contain 3 rows of header information.

- The first row is generally labelled with f1 through f## and is used to give a consistent column id to each data column. Do not remove this row unless instructed.

- The second row is labelled with the column data/field name. The values in this row are used for the file mapping screen. Editing these values is generally not needed and may make the field mapping process difficult.

- The third row (if present) is labelled either with the same values from row 2, or with more detailed field descriptions. The third row is available to create a customer-friendly name for the associated data column.

- The third row should be removed from the source file prior to importing. It will cause errors since it will be treated as the first import record on the file.

- Import files MUST always be saved as 'Microsoft Excel 5.0/95 Workbook (*.xls)' format until further notice. The import screens will generate errors if the file type is not correct.

- It is a good idea to perform a Mapping Table Import using a current source list before beginning on any imports. Without a current mapping table, the quality of imports can be compromised. The Mapping Table Import only needs to be run once on a newly set up Adjutant system. It does not need to be run before each import.

- Export a current list from the Mapping Table Import screen from an updated system (or contact your Implementation Consultant for an updated file).

- Perform a Mapping Table Import on the target system with the XLS file from the step above.

Bin Import Notes

The Coil Receipt Defaults screen sets the default values that prompt on coil tags as coils are received from purchase orders. The details in the attribute jump screen are defaults only, and can be overridden during the receiving process.

Timing and Preparation

The Coil Receipt Defaults Import can be run immediately after the Item Master Import to create and fill out the Coil Receipts Default attribute. The Coil Receipt Defaults attribute is also known as the COIL LOT or COILJUMP attribute.

The Coil Receipt Defaults attribute must be added for any coil item codes that will import coil lot#s and quantities with the Coil Import. The attribute can be empty, but it has to exist.

General Notes

The Coil Receipt Default Import will add the attribute if it doesn't already exist. If the attribute already exists, it will update the details in the COILJUMP screen.

Bin File Data Scrubbing

Every customer's data will have different issues that need addressing. Some of the issues will not make themselves visible until after the data has been imported and is in use during parallel testing. This is why it is critically important to perform an early import, and keep accurate notes on issues that need to be addressed on a supplemental import, or for a complete re-import. Some common things that need attention during Item Master data scrubbing include:

- Source Data - The customer may not have a file format that includes much of this data. It is common to need to create most of this data 'from scratch' and then have the customer fill in the remaining default data that they want. An easy way to get the source data for customers is to export a queried list from SQL (like the one below) that has the item, stock unit, and unit weight data. Customers can fill out the remaining details.

- select item, descrip, unit_stk, unitw from itemmaster where item like . . . . (change the query to list coil items)

- LBSFT - The SQL query above can help get the data needed to fill out the LBS/FT values if the unit weight data is complete on all of the coil items. If the LBSFT column is left empty, it will import a blank value.

- Processor - Review the COILPROCESSLIST CID Setup Option setting. With this turned on, the imported Processor Name value must EXACTLY match the company name of an organization set up with the PROCESSOR Organization attribute. If this option is off, any valid text wil import as the coil processor.

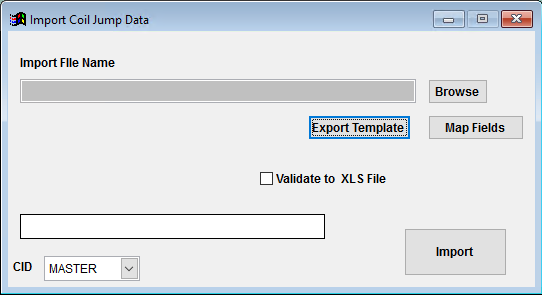

Bin Import Screen (IMPORTBINS)

Menu Location: Transaction>>Importers/Exporters>>Item Control>>Bin Import

File Name(Header)/Browse: Use the Browse button to locate and select the completed Coil Receipt Defaults template file (in XLS format).

Export Template: Generates a blank Coil Receipt Defaults template file

Map Fields: Fields must be mapped prior to importing. If no changes have been made to the column headings, the mapping screen should show all green, and you can click OK to continue. If any of the Input Field Name columns on the left are red, single-click on the line on the left column, and then double-click the desired mapped field in the right column to complete the mapping. Repeat for any red lines on the left that should be mapped. If there are additional columns in the source file that should NOT be mapped, they can be left unmapped (displayed in red). Mandatory fields will require that they be mapped before clicking OK.

Validate to XLS File: Generates a TXT file of errors that will prevent the import from completing.

Bin File Definitions

Required fields are indicated with an *

*f1 - Item - Item Master item code for the associated coil receipt defaults data. The item code must exist in Adjutant, or it will fail validation.

f2 - Grade - Default coil quality/grade code (10 alphanumeric character max)

f3 - Condition - Default coil condition code/description (10 alphanumeric character max)

f4 - Base Metal - Default coil base metal code/decsription (10 alphanumeric character max)

f5 - Backer - Default coil backer code/description (if any) (10 alphanumeric character max)

f6 - Thickness - Default coil material thickness, in inches

f7 - Coat - Default coil coating code/description (10 alphanumeric character max)

f8 - Mill - Default mill name (60 characters)

f9 - Processor - Default outside coil processor company name (60 characters). Processor name must EXACTLY match the Adjutant Organization name is COILPROCESSLIST is turned on.

f10 - Paint Code - Default paint Code value (10 alphanumeric character max)

f11 - HeatNo - Default heat number, can be used to default a prefix or a format (20 alphanumeric character max, some special characters allowed)

f12 - NumLabels - Default number of labels to print when receiving coil

f13 - CWidth - Default coil width (in inches). The width can be used as a filter in Coil Finder, so use the simplest expression of width possible. (i.e. use 43 instead of 42.9875)

f14 - LbsFT - Number of pounds for every 1 linear foot of coil

f15 - DefUnit - Default unit of measure, should generally match the stocking unit from the item

f16 - MasterCoil - Enter 'Y' to define the associated coil item as a Master coil

Bin Import Additional Steps

There are no additional steps needed after the import.

Bin Import Reconciliation

Reconciling imported data should begin with spot-checking several records field-by-field for complete data import. Pick records from the source file that have the most data columns filled in. Verify that all source file data fields imported correctly and display as expected.

Perform purchase order receipts for several different records and verify that receipt defaults and printing flags work as expected.

Bin Database Tables

PCXREF - Attributes added to item records will create cross-reference entries in the PCXREF table. The TYPE will generally be the attribute name or code. The PARENTID and CHILDID will generally match the IKEY value of the associated item.

COILJUMP - Attributes such as Catch Weight and Coil Receipt Defaults create their own data tables with details from the attribute jump screens. The associated FORM (jump screen) name from the ITEMATTRIB rule is generally the same name as the data table. These tables will usually link to the item using the IKEY value. Coil Receipt Default information is stored in the COILJUMP table linked to the IKEY of the associated item.