Difference between revisions of "Coil Import Guide"

From Adjutant Wiki

| (17 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | ==General Import | + | ==General Data Import Notes== |

| − | + | Refer to the [[Data Import General Information]] page for information and guidance on general import timeline, formatting import templates, as well as how to ensure you are using the most current template information for data imports. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 29: | Line 19: | ||

*Stock Item flag | *Stock Item flag | ||

*Lot# Control flag | *Lot# Control flag | ||

| + | *Unit Weight (per Stock Unit, not required, but it helps with verification) | ||

*Coil Receipt Defaults attribute (also known as COIL LOT or COILJUMP) | *Coil Receipt Defaults attribute (also known as COIL LOT or COILJUMP) | ||

*Purchase Units and Stock Units should be completed for all items with the correct units | *Purchase Units and Stock Units should be completed for all items with the correct units | ||

The import can automatically generate lot numbers for coils if the coil number (lot#) column is blank. Review the settings for the LOTNO counter in the 'Counters' tab of CID Maintenance prior to importing and verify that the numbering settings are correct. | The import can automatically generate lot numbers for coils if the coil number (lot#) column is blank. Review the settings for the LOTNO counter in the 'Counters' tab of CID Maintenance prior to importing and verify that the numbering settings are correct. | ||

| − | |||

| Line 41: | Line 31: | ||

Do not use the Coil Import for items with the Coil-Like Item (COIL LIKE) item attribute. The Coil Import is specifically designed for importing coil items with the cost expressed as cost per 100 lbs of material, and items with the COIL LIKE attribute may import with unexpected costs. Use the Inventory Qty Import for non-coil items. | Do not use the Coil Import for items with the Coil-Like Item (COIL LIKE) item attribute. The Coil Import is specifically designed for importing coil items with the cost expressed as cost per 100 lbs of material, and items with the COIL LIKE attribute may import with unexpected costs. Use the Inventory Qty Import for non-coil items. | ||

| − | + | The Coil Import will add Item Master records for any item code on the import that doesn't already exist in Adjutant. The system-added Item Master records will be incomplete, and should be reviewed and updated to make sure the item settings are correct. | |

| − | Review the | + | Review the '''COILPROCESSLIST''' CID Setup Option setting. With this turned on, the imported Processor Name value must exactly match the company name of an organization set up with the PROCESSOR Organization attribute. If this option is off, any valid text wil import as the coil processor. |

| − | ''coil cost | + | Review the '''POCOILLBS''' CID Setup Option setting. With this turned on, the coil import assumes coil is stocked in LBS and the catch-weight calculation uses FT. This can affect the cost calculations. Best practices for coil inventory are to stock in FT, so for the majority of customers, this option should be turned off. |

| + | '''Coil Cost (Stocked in FT):''' The coil cost (column f5 in the template) should be entered and imported as cost per hundred LBS (catch-weight). The import process will convert and import the cost correctly as long as the cost is expressed in catch-weight, and the linear feet and actual weight columns are correct. | ||

| + | *If the customer data includes cost per LB, simply multiply that number by 100 to use as the cost. | ||

| + | *If the customer data includes cost per FT, multiply the cost/FT times the Linear Feet to get a total cost for the coil. Divide the calculated total cost by the Actual Weight value to get a cost/LB. Multiply the cost/LB times 100 to get the catch-weight cost. | ||

| + | *If the customer data only includes a total cost for the coil, divide the total cost by the Actual Weight to get a cost/LB. Multiple the cost/LB to get the catch-weight cost. See other considerations below. | ||

| + | |||

| + | '''Coil Cost (Stocked in LBS):''' Verify the the '''POCOILLBS''' setup option is turned on if the customer is stocking in LBS. The coil cost (column f5 in the template) should be entered and imported as cost per hundred LBS (catch-weight), which is the same procedure to use as when stocking in FT. With the setup option turned on, the import process will convert and import the cost correctly as long as the cost is expressed in catch-weight, and the linear feet and actual weight columns are correct. | ||

| + | |||

| + | '''Coil Cost (other considerations):''' If the source data does not include a fixed cost per unit (either LBS or FT), and only includes a total cost per coil, be very careful that the cost does not include used material. For example, if you import a coil with an original total cost of $5000, but that coil has been partially used prior to import, you would get an inflated cost per unit if you only used the remaining quantity to calculate cost/LB. If 10,000 LBS of coil originally cost $5,000, that is .50/LB. However, if you are only importing the remaining 2,500 LBS of that coil and used the total cost of $5000, you would import a cost of $2/LB. If you are using an original cost total, you need to obtain an original quantity total to calculate the correct cost per unit. | ||

| Line 54: | Line 52: | ||

Every customer's data will have different issues that need addressing. Some of the issues will not make themselves visible until after the data has been imported and is in use during parallel testing. This is why it is critically important to perform an early import, and keep accurate notes on issues that need to be addressed on a supplemental import, or for a complete re-import. Some common things that need attention during Item Master data scrubbing include: | Every customer's data will have different issues that need addressing. Some of the issues will not make themselves visible until after the data has been imported and is in use during parallel testing. This is why it is critically important to perform an early import, and keep accurate notes on issues that need to be addressed on a supplemental import, or for a complete re-import. Some common things that need attention during Item Master data scrubbing include: | ||

| − | * ''' | + | * '''Date Received''' - Every imported coil should have a date received value. The import process will not auto-fill the date received if the column is left empty. If an original date received cannot be provided, work with the customer to decide on a date value to use for all empty records. |

| − | * '''Cost''' - Verify that the | + | * '''Cost''' - Verify that the cost per 100 LBS is entered for each item. See General Notes area above for cost calculations. Cost can be an extremely difficult item to correct once the item has been used in live transactions. Double-check the cost values carefully. |

| − | |||

| − | |||

| + | * '''Coil Number''' - This converts to LOT#. Work with the customer to confirm whether they want to continue using the same lot numbers, manually assign new ones, or let the system auto-assign lot numbers based on the system counters. | ||

| Line 67: | Line 64: | ||

Menu Location: Transaction>>Importers/Exporters>>Item Control>>Coil Import | Menu Location: Transaction>>Importers/Exporters>>Item Control>>Coil Import | ||

| − | [[File: | + | [[File:Coil_Import.png]] |

| + | '''Item File Name/Browse:''' Use the Browse button to locate and select the completed Coil import template file (in XLS format). | ||

| − | + | '''Export Template:''' Generates a blank Coil import template file | |

| − | |||

| − | '''Export Template:''' Generates a blank | ||

'''Map Fields:''' Fields must be mapped prior to importing. If no changes have been made to the column headings, the mapping screen should show all green, and you can click OK to continue. If any of the Input Field Name columns on the left are red, single-click on the line on the left column, and then double-click the desired mapped field in the right column to complete the mapping. Repeat for any red lines on the left that should be mapped. If there are additional columns in the source file that should NOT be mapped, they can be left unmapped (displayed in red). Mandatory fields will require that they be mapped before clicking OK. | '''Map Fields:''' Fields must be mapped prior to importing. If no changes have been made to the column headings, the mapping screen should show all green, and you can click OK to continue. If any of the Input Field Name columns on the left are red, single-click on the line on the left column, and then double-click the desired mapped field in the right column to complete the mapping. Repeat for any red lines on the left that should be mapped. If there are additional columns in the source file that should NOT be mapped, they can be left unmapped (displayed in red). Mandatory fields will require that they be mapped before clicking OK. | ||

| − | '''Default | + | '''Default Owner:''' Sets the inventory owner for all imported coil records. This list is populated with Organization records that have the Inventory Owner attribute. |

| − | '''Default | + | '''Default Warehouse:''' Sets the warehouse location for all imported coil records. This list is populated by Warehouse Control records that have been created. |

| − | '''Default HedlFor:''' Sets the inventory holder for | + | '''Default HedlFor:''' Sets the inventory holder for all imported coil records. This list is populated from the Item Held For Codes (HOLDER) Rule Maintenance record. If a catch-all code such as 'DEF' is used, make sure the HOLDER rule is set up properly. |

| − | |||

| − | |||

| − | + | ==Coil Import File Definitions== | |

| − | + | Required fields are indicated with an * | |

| − | ''' | + | '''f1 - Mill Coil#''' - Mill original coil number (20 alphanumeric character max, some special characters allowed) |

| − | ''' | + | '''f2 - Processor Name''' - Outside coil processor company name (60 characters). Processor name must EXACTLY match the Adjutant Organization name is COILPROCESSLIST is turned on. |

| − | ''' | + | '''f3 - Processor #''' - Processor coil number (20 alphanumeric character max, some special characters allowed) |

| + | '''f4 - Paint Code''' - Paint Code value (10 alphanumeric character max) | ||

| + | '''*f5 - Cost''' - Coil cost per 100 LBS. Use the cost per 100 LBS whether stocking the coil in FT or in LBS. The coil import process will convert the cost appropriately. | ||

| − | + | '''f6 - Print''' - Enter 'N' to indicate that a coil tag should not be printed for this coil. A blank entry is imported as 'Y'. | |

| − | + | '''f7 - Width''' - Coil width (in inches). The width can be used as a filter in Coil Finder, so use the simplest expression of width possible. (i.e. use 43 instead of 42.9875) | |

| − | ''' | + | '''f8 - HeatNo''' - Original heat number (20 alphanumeric character max, some special characters allowed) |

| − | '''* | + | '''*f9 - Coil Number''' - Coil Lot # in Adjutant. If left blank, and the CID Maintenance LOT counter is set up, records will be automatically assigned a Lot #. |

| − | '''* | + | '''*f10 - Date Received''' - Original coil receipt date. Leaving the date blank imports an empty receipt date. |

| − | ''' | + | '''f11 - Received By''' - Name, USERID, or initials of receiving person |

| − | '''* | + | '''*f12 - Inventory#''' - Item Master item code for the associated lot record. If the item code does not already exist, the import process will create a placeholder item code with the item and description from the file. All placeholder item codes should be reviewed and updated in Item Master. |

| − | '''* | + | '''*f13 - Linear Feet''' - Total available linear feet for the associated lot record |

| − | ''' | + | '''f14 - Theo Weight''' - Theoretical weight for the associated lot record (LBS) |

| − | '''* | + | '''*f15 - Actual Weight''' - Total available pounds of coil for the associated lot record |

| − | ''' | + | '''f16 - Description''' - Coil description override. If left blank, the item code description will be used. The entered description will be used for the associated coil tag. |

| − | ''' | + | '''f17 - Grade''' - Coil quality/grade code (10 alphanumeric character max) |

| − | ''' | + | '''f18 - Condition''' - Coil condition code/description (10 alphanumeric character max) |

| − | ''' | + | '''f19 - Base Metal''' - Coil base metal code/decsription (10 alphanumeric character max) |

| − | ''' | + | '''f20 - Backer''' - Coil backer code/description (if any) (10 alphanumeric character max) |

| − | ''' | + | '''f21 - Thickness''' - Coil material thickness, in inches |

| − | ''' | + | '''f22 - Coat''' - Coil coating code/description (10 alphanumeric character max) |

| − | ''' | + | '''f23 - Vendor''' - Original Vendor name from the receiving PO (60 characters) |

| − | ''' | + | '''f24 - PO#''' - Original PO# |

| − | ''' | + | '''f25 - Mill Name''' - Original mill name (60 characters) |

| − | |||

| − | |||

| − | + | ==Coil Import Additional Steps== | |

| − | ''' | + | '''IMPORTANT!!''' - Perform the Cost Tiers Import for every imported lot record to establish the historical receipt cost tier. The purchase order receipt process automatically builds cost tier data, but the coil import process does not create cost tier data. Failing to import cost tiers for the imported coils can have adverse effects down the road during inventory, procurement, and production processes. Follow the [[Cost Tiers Import Guide]] for details on importing cost tiers. |

| − | + | Perform the Coil Receipt Defaults (COILJUMP) import to set the default coil receipt tag values for each coil item. Follow the [[Coil Receipt Defaults Import Guide]] for details. | |

| − | + | Run the Update Item OH/AL/OO (ITEMUPDATE) report after all coil lots have been imported. This will update the Item Master on hand displays and item search results with the imported values. | |

| − | + | Print coil tags for all imported coils. | |

| + | *During parallel testing, it is okay to only print coil tags for selected items that will be used for testing. All coil item types should be tested (i.e. coil for panels, coil for cees, etc.) | ||

| − | + | *For go-live, all imported coil records must have coil tags printed. | |

| − | |||

| − | |||

| − | |||

| − | + | ==Coil Import Reconciliation== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | ||

Reconciling imported data should begin with spot-checking several records field-by-field for complete data import. Pick records from the source file that have the most data columns filled in. Verify that all source file data fields imported correctly and display as expected. | Reconciling imported data should begin with spot-checking several records field-by-field for complete data import. Pick records from the source file that have the most data columns filled in. Verify that all source file data fields imported correctly and display as expected. | ||

| − | Run the | + | Run the Inventory On Hand Report filtered for the imported records and verify that the imported records all display as expected. Review the lots, cost entries, and on hand value for all imported lot records. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | Perform several searches in the Coil Finder screen to make sure that imported coils show up as expected. Review the coil tags and make sure they print as expected. | ||

| − | + | Compare the Adjutant cost and on hand inventory value for several records against the source data. Verify that imported coil inventory value matches the source data value. If there are any discrepancies, review, adjust, and try to correct with an updated import. If the differences can't be corrected with a new import, document the reasons for the differences and discuss with customer. | |

| − | Complete the | + | Complete different types of production with the imported coils and verify that lot records are available for production assignments. Verify that cost accounting for production usage is accurate. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | ==Coil Import Database Tables== | ||

| − | + | '''COILRECEIPT''' - Each imported lot creates a KEYNO in this table, linked to the imported LOT and tied to the item's IKEY. | |

| − | ''' | + | '''ITEMTRACK''' - Each imported lot creates a TRACKNO in this table, linked to the imported LOT and tied to the item's IKEY. |

| − | ''' | + | '''ITEMMASTER''' - Any coil item that doesn't already exist will create a unique IKEY tied to the ITEM value. |

| − | ''' | + | '''ITEMMDET''' - Any coil item that doesn't already exist will also create a unique ITEMDET record for the OHF combination specified on the import screen. |

| − | |||

[[Category: Item Control]] | [[Category: Item Control]] | ||

[[Category: Import Guides]] | [[Category: Import Guides]] | ||

Latest revision as of 10:55, 8 April 2024

Contents

General Data Import Notes

Refer to the Data Import General Information page for information and guidance on general import timeline, formatting import templates, as well as how to ensure you are using the most current template information for data imports.

Coil Import Notes

Timing and Preparation

The Coil Import is a quantity import, and should occur after all of the coil item records have been imported. An early Coil Import should be completed for parallel testing to create available coil inventory to test production of several types of produced coil material. Testing the coil import early can help find any data issues that show up during the production, inventory reporting, and inventory valuation testing procedures. The Item Control rules should be complete prior to importing item master records. The Item Control Setup Guide covers all of the Rule Maintenance records that should be completed prior to importing item master records.

Coil import files should be separated into multiple imports based on the combination of Owner/HeldFor/Warehouse (OFH). The import template does not have data columns for OHF data, so if coils need to be imported to specific OHF combinations, the data will need to be separated into multiple files and the OHF values must be specified at the time of import. If all coils should be stocked under the same OHF details, you can still separate the coil files by item type, department, category, or any number of item grouping details if it makes formatting or reconciling inventory values easier. However, it is not required.

The Coil Import will need to be run again at go-live to import the final available coil inventory as of the go-live date. A 'difference conversion' or 'catch-up conversion' is generally not worth it after coil quantities have been used in testing, and after purchase order coil receipts have been completed during testing. The best practice is to delete all of the coil inventory and re-import with the current, final on hand coil quantities at go-live.

Coil Items should all have the following settings (at a minimum) in Item Master:

- Stock Item flag

- Lot# Control flag

- Unit Weight (per Stock Unit, not required, but it helps with verification)

- Coil Receipt Defaults attribute (also known as COIL LOT or COILJUMP)

- Purchase Units and Stock Units should be completed for all items with the correct units

The import can automatically generate lot numbers for coils if the coil number (lot#) column is blank. Review the settings for the LOTNO counter in the 'Counters' tab of CID Maintenance prior to importing and verify that the numbering settings are correct.

General Notes

Do not use the Coil Import for items with the Coil-Like Item (COIL LIKE) item attribute. The Coil Import is specifically designed for importing coil items with the cost expressed as cost per 100 lbs of material, and items with the COIL LIKE attribute may import with unexpected costs. Use the Inventory Qty Import for non-coil items.

The Coil Import will add Item Master records for any item code on the import that doesn't already exist in Adjutant. The system-added Item Master records will be incomplete, and should be reviewed and updated to make sure the item settings are correct.

Review the COILPROCESSLIST CID Setup Option setting. With this turned on, the imported Processor Name value must exactly match the company name of an organization set up with the PROCESSOR Organization attribute. If this option is off, any valid text wil import as the coil processor.

Review the POCOILLBS CID Setup Option setting. With this turned on, the coil import assumes coil is stocked in LBS and the catch-weight calculation uses FT. This can affect the cost calculations. Best practices for coil inventory are to stock in FT, so for the majority of customers, this option should be turned off.

Coil Cost (Stocked in FT): The coil cost (column f5 in the template) should be entered and imported as cost per hundred LBS (catch-weight). The import process will convert and import the cost correctly as long as the cost is expressed in catch-weight, and the linear feet and actual weight columns are correct.

- If the customer data includes cost per LB, simply multiply that number by 100 to use as the cost.

- If the customer data includes cost per FT, multiply the cost/FT times the Linear Feet to get a total cost for the coil. Divide the calculated total cost by the Actual Weight value to get a cost/LB. Multiply the cost/LB times 100 to get the catch-weight cost.

- If the customer data only includes a total cost for the coil, divide the total cost by the Actual Weight to get a cost/LB. Multiple the cost/LB to get the catch-weight cost. See other considerations below.

Coil Cost (Stocked in LBS): Verify the the POCOILLBS setup option is turned on if the customer is stocking in LBS. The coil cost (column f5 in the template) should be entered and imported as cost per hundred LBS (catch-weight), which is the same procedure to use as when stocking in FT. With the setup option turned on, the import process will convert and import the cost correctly as long as the cost is expressed in catch-weight, and the linear feet and actual weight columns are correct.

Coil Cost (other considerations): If the source data does not include a fixed cost per unit (either LBS or FT), and only includes a total cost per coil, be very careful that the cost does not include used material. For example, if you import a coil with an original total cost of $5000, but that coil has been partially used prior to import, you would get an inflated cost per unit if you only used the remaining quantity to calculate cost/LB. If 10,000 LBS of coil originally cost $5,000, that is .50/LB. However, if you are only importing the remaining 2,500 LBS of that coil and used the total cost of $5000, you would import a cost of $2/LB. If you are using an original cost total, you need to obtain an original quantity total to calculate the correct cost per unit.

Coil Import File Data Scrubbing

Every customer's data will have different issues that need addressing. Some of the issues will not make themselves visible until after the data has been imported and is in use during parallel testing. This is why it is critically important to perform an early import, and keep accurate notes on issues that need to be addressed on a supplemental import, or for a complete re-import. Some common things that need attention during Item Master data scrubbing include:

- Date Received - Every imported coil should have a date received value. The import process will not auto-fill the date received if the column is left empty. If an original date received cannot be provided, work with the customer to decide on a date value to use for all empty records.

- Cost - Verify that the cost per 100 LBS is entered for each item. See General Notes area above for cost calculations. Cost can be an extremely difficult item to correct once the item has been used in live transactions. Double-check the cost values carefully.

- Coil Number - This converts to LOT#. Work with the customer to confirm whether they want to continue using the same lot numbers, manually assign new ones, or let the system auto-assign lot numbers based on the system counters.

Coil Import Screen (ITEMIMPORTSBS1)

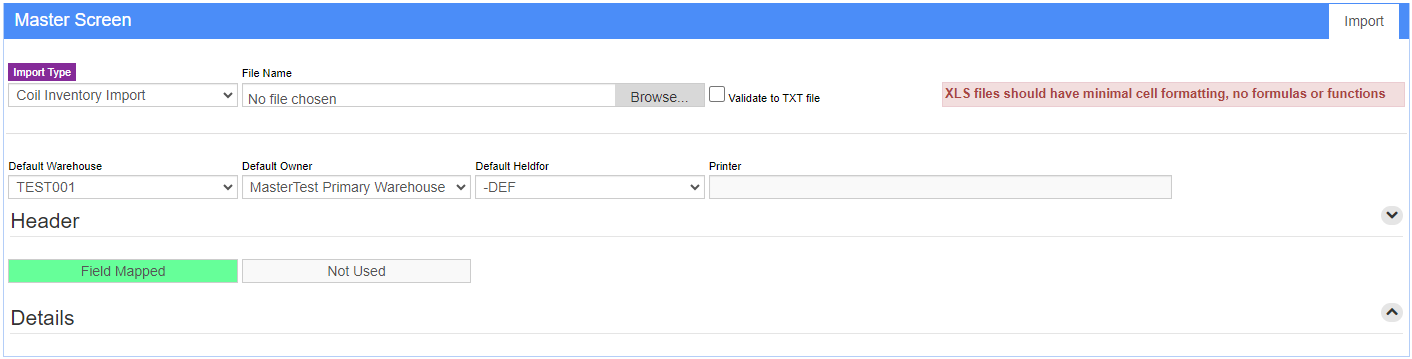

Menu Location: Transaction>>Importers/Exporters>>Item Control>>Coil Import

Item File Name/Browse: Use the Browse button to locate and select the completed Coil import template file (in XLS format).

Export Template: Generates a blank Coil import template file

Map Fields: Fields must be mapped prior to importing. If no changes have been made to the column headings, the mapping screen should show all green, and you can click OK to continue. If any of the Input Field Name columns on the left are red, single-click on the line on the left column, and then double-click the desired mapped field in the right column to complete the mapping. Repeat for any red lines on the left that should be mapped. If there are additional columns in the source file that should NOT be mapped, they can be left unmapped (displayed in red). Mandatory fields will require that they be mapped before clicking OK.

Default Owner: Sets the inventory owner for all imported coil records. This list is populated with Organization records that have the Inventory Owner attribute.

Default Warehouse: Sets the warehouse location for all imported coil records. This list is populated by Warehouse Control records that have been created.

Default HedlFor: Sets the inventory holder for all imported coil records. This list is populated from the Item Held For Codes (HOLDER) Rule Maintenance record. If a catch-all code such as 'DEF' is used, make sure the HOLDER rule is set up properly.

Coil Import File Definitions

Required fields are indicated with an *

f1 - Mill Coil# - Mill original coil number (20 alphanumeric character max, some special characters allowed)

f2 - Processor Name - Outside coil processor company name (60 characters). Processor name must EXACTLY match the Adjutant Organization name is COILPROCESSLIST is turned on.

f3 - Processor # - Processor coil number (20 alphanumeric character max, some special characters allowed)

f4 - Paint Code - Paint Code value (10 alphanumeric character max)

*f5 - Cost - Coil cost per 100 LBS. Use the cost per 100 LBS whether stocking the coil in FT or in LBS. The coil import process will convert the cost appropriately.

f6 - Print - Enter 'N' to indicate that a coil tag should not be printed for this coil. A blank entry is imported as 'Y'.

f7 - Width - Coil width (in inches). The width can be used as a filter in Coil Finder, so use the simplest expression of width possible. (i.e. use 43 instead of 42.9875)

f8 - HeatNo - Original heat number (20 alphanumeric character max, some special characters allowed)

*f9 - Coil Number - Coil Lot # in Adjutant. If left blank, and the CID Maintenance LOT counter is set up, records will be automatically assigned a Lot #.

*f10 - Date Received - Original coil receipt date. Leaving the date blank imports an empty receipt date.

f11 - Received By - Name, USERID, or initials of receiving person

*f12 - Inventory# - Item Master item code for the associated lot record. If the item code does not already exist, the import process will create a placeholder item code with the item and description from the file. All placeholder item codes should be reviewed and updated in Item Master.

*f13 - Linear Feet - Total available linear feet for the associated lot record

f14 - Theo Weight - Theoretical weight for the associated lot record (LBS)

*f15 - Actual Weight - Total available pounds of coil for the associated lot record

f16 - Description - Coil description override. If left blank, the item code description will be used. The entered description will be used for the associated coil tag.

f17 - Grade - Coil quality/grade code (10 alphanumeric character max)

f18 - Condition - Coil condition code/description (10 alphanumeric character max)

f19 - Base Metal - Coil base metal code/decsription (10 alphanumeric character max)

f20 - Backer - Coil backer code/description (if any) (10 alphanumeric character max)

f21 - Thickness - Coil material thickness, in inches

f22 - Coat - Coil coating code/description (10 alphanumeric character max)

f23 - Vendor - Original Vendor name from the receiving PO (60 characters)

f24 - PO# - Original PO#

f25 - Mill Name - Original mill name (60 characters)

Coil Import Additional Steps

IMPORTANT!! - Perform the Cost Tiers Import for every imported lot record to establish the historical receipt cost tier. The purchase order receipt process automatically builds cost tier data, but the coil import process does not create cost tier data. Failing to import cost tiers for the imported coils can have adverse effects down the road during inventory, procurement, and production processes. Follow the Cost Tiers Import Guide for details on importing cost tiers.

Perform the Coil Receipt Defaults (COILJUMP) import to set the default coil receipt tag values for each coil item. Follow the Coil Receipt Defaults Import Guide for details.

Run the Update Item OH/AL/OO (ITEMUPDATE) report after all coil lots have been imported. This will update the Item Master on hand displays and item search results with the imported values.

Print coil tags for all imported coils.

- During parallel testing, it is okay to only print coil tags for selected items that will be used for testing. All coil item types should be tested (i.e. coil for panels, coil for cees, etc.)

- For go-live, all imported coil records must have coil tags printed.

Coil Import Reconciliation

Reconciling imported data should begin with spot-checking several records field-by-field for complete data import. Pick records from the source file that have the most data columns filled in. Verify that all source file data fields imported correctly and display as expected.

Run the Inventory On Hand Report filtered for the imported records and verify that the imported records all display as expected. Review the lots, cost entries, and on hand value for all imported lot records.

Perform several searches in the Coil Finder screen to make sure that imported coils show up as expected. Review the coil tags and make sure they print as expected.

Compare the Adjutant cost and on hand inventory value for several records against the source data. Verify that imported coil inventory value matches the source data value. If there are any discrepancies, review, adjust, and try to correct with an updated import. If the differences can't be corrected with a new import, document the reasons for the differences and discuss with customer.

Complete different types of production with the imported coils and verify that lot records are available for production assignments. Verify that cost accounting for production usage is accurate.

Coil Import Database Tables

COILRECEIPT - Each imported lot creates a KEYNO in this table, linked to the imported LOT and tied to the item's IKEY.

ITEMTRACK - Each imported lot creates a TRACKNO in this table, linked to the imported LOT and tied to the item's IKEY.

ITEMMASTER - Any coil item that doesn't already exist will create a unique IKEY tied to the ITEM value.

ITEMMDET - Any coil item that doesn't already exist will also create a unique ITEMDET record for the OHF combination specified on the import screen.