General Information

Default Menu Location Maintain >> Item Control >> Item Master

Screen Name JUMP2

Function Item Control is a scalable inventory and item management solution that tracks inventory levels, costs, prices, transaction history, inventory locations, and much more. Complex pricing for purchasing and sales is easily maintained through separate item pricing and product groups. The Item Control module also allows you to maintain costs on several levels and automatically update costs based on multiple variables. It handles an unlimited number of warehouse locations, serialized items, and lot-controlled items and allows for the inclusion of freight in/out, direct, and indirect costs of the item. Attach notes to any item that automatically print on purchase orders, quotes, sales orders, and invoices. Easy-to-use search features make finding similar/substitution items a breeze and a wide-ranging drill-down tool gives you insight into any item in your database.

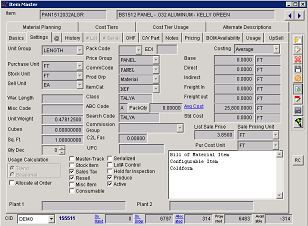

Item Master Screen |

Basic

Item Master - BasicsToday's Prices is no longer used.

The rules for pricing display is maintained in the

Rule Maintenance screen by selecting Pricing for Basics from the drop-down menu.

Fields/Filters

Default Supplier: Default supplier/vendor for this item

Supplier Part#: Default supplier's part number for this item

Unit Group: Unit group for this item

Stock Unit: Stocking unit for this item

Price Group: Price group for this item

Product Group: Product group for this item

Item GL Code: Item Transaction Category for this item

Base Cost: Base cost for this item

List Sale Price: List sale price for this item

Sale Pricing Unit: The unit this item is priced by

Projected: (On Hand + On Order) - Allocated

Available: On Hand - Allocated

Settings

Settings tab is used to maintain the item's main properties.

Fields/Filters

Lot #: Used for tracking of inventory. Also used to look up items for recall if an item is bad.

Unit Group: The unit of measure group for this item

Purchase Unit: The default unit of measure for purchase

Stock Unit: The unit of measure the item stocked

Sell Unit: The default unit of measure for sale

Units of measure and their conversions (Unit Groups) are maintained in the

Rule Maintenance screen under Units of Measure.

War. Length: The warranty length for a produced item

Misc Code: User defined field

Unit Weight: Each unit's stock weight

Cubes: Another way of measuring the volume of an item. Case cube denotes how much volume a case of any given item will take up in your warehouse, can be in cubic feet or cubic meters.

Sq. Ft: The square footage of the item

Qty Dec: The quantity of decimal places allowed when entering a quantity of the item

Allocate at Order: Check this box if the item is lot controlled and you want to be able to allocate specific lots when entering a Sales Order.

Master-Track: This assigns a different PackID to items receipted under the same lot number. For example, if you receipt 1000 feet of coil under lot# 1234, then perform a separate receipt of 500 feet under the same lot number (1234), then these receipts will display on separate lines in the #Lot tab of Item Master. Each line will have a separate PackID number even though the lot numbers are the same.

Stock Item: Stocked in a warehouse

Sales Tax: The item will have applicable sales tax

Resell: To add the item on a sales order. If unchecked, this will also add tax to the receipted amount on a PO, provided the vendor has a tax amount in the Remit To screen of their Organization record.

Misc Item: Miscellaneous item (This will allow you to edit the item's description when it is used on a service order.)

Serialized: Check this box if you wish to track the item's serial numbers (All received serialized items will be logged as assets in the Asset Information screen.)

Lot # Control: Check this box if you wish the item to be lot controlled

Expiration Date: Check this box if the item has an expiration date (You will be required to enter an expiration date when this item is received.)

Hold For Inspection: Check this box if the item needs to be held for inspection upon arrival

Produce: Check this box if the item is run through production in order to be created

Active: Check this box if the item is active within your system (Leaving this box unchecked makes the item completely unusable.)

Track Length: There is a lot of logic behind this option.

Click here to learn more. Pack Code: Used to signify what can be packed together, it is not very commonly used.

Price Group: The item's Price Group

- Price Groups are used to determine pricing in the Contract Master and are also used to determine margins in the Margin Calculator

- Price Groups are maintained in the Rule Maintenance Screen by selecting Item Pricing Codes from the drop-down menu

Comm Code: The item's Commodity Code

- Commodity Codes are used in the procurement system to Generate Vendor Inquiries

- Commodity Codes are maintained in the Rule Maintenance Screen by selecting Item Commodity Codes from the drop-down menu

Prod Grp: The item's Product Group

- Product Groups are used to determine pricing inthe Contract Master

- Product Groups are maintained in the Rule Maintenance screen under Item Product Group Codes

Item Cat: Select the item's general ledger code

- Item Categories are maintained in the Rule Maintenance screen under Item Transaction Codes

Class: User defined field (Some inventory reports may be sorted by class)

ABC Code: The ABC Code is calculated based on item usage or on-hand value

- ABC codes are maintained in the Manage ABC Codes screen

Search Code: Similar/like/alternate items can have the same search code and be brought up on a list when clicking the button

Commission Code: Select the commission code for the item

- Commission codes are maintained in the Rule Maintenance screen under Commission Percentage Codes

C2L Factor: C2L Factor (Cost2List) is used to make dummy list prices for misc items:

Example:

If the cost is 5.00, and the Cl2 is 2.5, then the list price is 12.50

5 * 2.5

Base Cost: The base cost of the item according to Stock Unit

- This cost is used as a base for the cost-plus calculations performed on the Group Pricing tab of the Contract Master

- The base cost will be updated based on PO Receipts if the Update BCost on Receipt attribute is selected

Direct Cost: Enter any direct costs associated with the item here

Indirect Cost: Enter any indirect costs associated with the item here

Freight In Cost: Enter the freight costs associated with receiving the item into inventory

Freight Out Cost: Enter the freight costs associated with shipping the item

Avg Cost: Average Cost is the system-maintained, weighted average cost of the inventory item

- This cost is used for inventory on-hand reports and monthly activity reports

- This is also the cost that is transferred to the GL

List Sale Price: The item's list sale price

- This price is used to price the item if no other contract rule can be applied to the part

Sale Pricing Unit: The unit of measure used to determine the item's pricing

EDI: Electronic Data Interchange. This is a type of invoicing used by many corporations; It is somewhat dated. It is the transfer of data from one computer system to another by standardized message formatting without the need for human intervention. EDI permits multiple companies, possibly in different countries, to exchange documents electronically.

Consumable: Item is purchased for overhead or internal use, will not be sold. Allows an item to be purchased without being linked to a sales order.

Commission Group: Used for items that pay different commission percentages to sales force.

"@"

Item Master - @The @ tab of the Item Master displays the locations of the item selected.

Fields/Filters

Rack#: Rack number in the warehouse

Current Qty: Current Quantity

Location: Warehouse location

Held For: Inventory being held for

Supplier: Supplier company

Track#: Tracking number

Owner: Inventory owner

CW Qty: Catch Weight quantity

Serial: Serial number

Lot: Lot number

VarUnit: Variable Unit

VarQty: Variable Quantity

Packed Button The Packed button will pop up a grid display of cartons that contain the selected item. The grid displays key information such as carton ID, packed quantity, linked Sales Order, and SO status. Lines displayed in green indicate that the linked order is still open. Lines displayed in red indicate that the linked order has been closed or voided, but a quantity remains packed in the carton.

History

Item Master - History

History tab contains information about all transactions concerning the selected item. It displays the items transfer, adjustments, receipts, usage, etc.

- You may sort the grid by whichever column you choose by clicking on the column name

- Enter a range of dates to view a specific date range, or select All to view all history

- Click Print button to display the Message Control Screen

Fields/Filters

The fields on this tab are pretty much self explanatory:

- Trans Date

- Qty

- Whse

- Type

- Order#

- CustVend

- Serial/Lot

- UserID

- Dept

Lot#

Item Master - Lot#The Lot # tab displays information concerning lot controlled items.

Fields/Filters

The Fields on this tab are also self explanatory:

- Lot#

- Rack#

- Qty in Lot

- PackID

- Whse

- CW Qty

- Cost/StkUnit

- Cost/CWUnit

- CWUnit

- VarUnit

- VarQty

- CountryOrigin

- Owner

Serial#

Item Master - Serial#Users can filter the entire inventory by

Serial#,

Rack#, or

WarehouseFields/Filters

Here is a list of fields on this tab:

- Serial#

- Rack#

- PackID

- Whse

- VarUnit

- VarQty

OHF

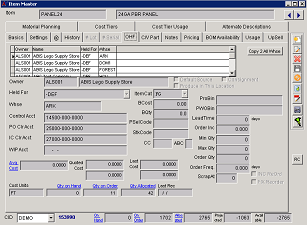

Item Master OHF Tab |

OHF tab is used to determine which items may be stored and/or distributed out of which warehouses.

- Click New to add a new Owner/Held For (This allows you to add this item to the warehouse)

- Enter the Owner of the item (Owners are set up in the Organization Screen with an attribute of Inventory Owner.)

- Enter who the item is Held For (Inventory Holders are maintained in the Rule Maintenance screen under Holders)

- Enter the Whse (Warehouse) the item is to be placed in, or come out of (Warehouses are set up in the Warehouses screen)

- Select the Item GL Code (the item's General Ledger code) (Item GL Codes are maintained in the Rule Maintenance screen under Item Transaction Codes)

- Click the Produce in this location flag for the appropriate warehouses, and Bin Locations (if needed). See the Settings Tab for correct set up of Produced Items.

- Enter the appropriate account numbers if necessary (The warehouse selected will default it's Control, PO Clearing, and Inventory Control Clearing Account numbers.)

- Click Save button when finished

- Click Copy 2 All Whse to add the item to all warehouses (Doing this lets you receive into and distribute this item out of those warehouses.)

Fields/Filters

Owner: Owner of the items

Held For: An entity that can reserve the items

Whse: Warehouse that stores the items

CC: Cycle count code, used to segment out cycle counts

ScrapAt: Tells the system what level to scrap the item qty at

Default Source: Check this box to make the Owner/Held For/Whse the defaults when placing orders

PWO Buyout: Checking this box on a specific OHF record overrides the Production S2P logic for the selected OHF and allows the item to show up as a buyout item in QuickBuy. If this box is checked, SO items for that OHF will not be submitted to production.

Item GL Code: The item transaction category for the item based on Owner/Held For/Whse

Control Acct: Item control (inventory) account for the item (The warehouse default accounts will populate these fields)

PO Clr Acct: PO clearing account for the items

IC Clr Acct: Item control clearing account for the items. Used to offset inventory adjustments.

Base: Base cost of the item based on Owner/Held For/Whse

Direct: Direct cost of the item based on Owner/Held For/Whse

Indirect: Indirect cost of the item based on Owner/Held For/Whse

Freight: Freight cost of the item based on Owner/Held For/Whse

Last Cost: The last received cost for the item based on Owner/Held For/Whse

Qty on Hand: Current quantity on hand based on Owner/Held For/Whse

Qty on Order: Quantity on order (open purchase orders) based on Owner/Held For/Whse

Qty Allocated: Quantity allocated (open sales orders) based on Owner/Held For/Whse

Last Rec: Date of the last PO receipt for the items based on for Owner/Held For/Whse

Usage: Average usage of the items (per week) based on Owner/Held For/Whse

ProBin: Bin number in which the items to be stocked based on Owner/Held For/Whse. Items produced on Build For Stock work orders will go into this bin by default.

PWOBin: Bin number in which the items to be stocked based on Owner/Held For/Whse. Stocked items produced on regular work orders (ones linked to a sales order) will go into this bin by default.

Lead Time: Average lead time (in days) to order and receive the items based on Owner/Held For/Whse. This is used when creating a purchase order from Quick Buy to determine the estimated delivery date on the purchase order.

Order Inc: Order increment quantity. Item must be purchased in increments of the qty entered here.

Min Qty: Minimum on hand quantity for the item; aka Order Point. Quick Buy will trigger you to replenish the item when Projected Qty is less than or equal to Min Qty.

Max Qty: Maximum on hand quantity for the item. Quick Buy will not recommend that you purchase above this quantity.

Order Qty: Almost always the difference between Max and Min quantity. Order Qty is used in the RRQ calculation in Quick Buy.

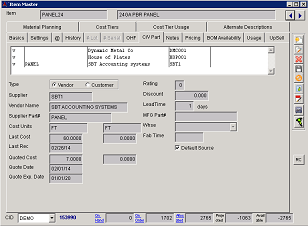

Customer/Vendor Part (C/V Part)

Item Master C/V Tab |

The Customer/Vendor Part tab is used to maintain vendor and customer part numbers for your item codes.

Vendor part numbers will be automatically entered in the Purchase Orders screen when an item is entered. You can also search by vendor part number when entering a line item on a Purchase Order.

Customer part numbers will be automatically entered in the Sales Orders screen when an item is entered. You can also search by customer part number when entering a line item on a Sales Order.

Depending on your custom forms, the respective vendor/customer part numbers will also print on the PO/SO.

Click the ADD button to add a new part number, then select either Vendor or Customer accordingly.

Vendor

Supplier: The vendor's Organization ID and Name

Supplier Part#: The vendor's part number for this item

Default Source: Check this box if the vendor is your default source for this item.

Last Cost: The last received cost for this item (from the vendor).

Last Rec: The date of the last PO receipt for this item.

Quoted Cost: The last quoted cost from the vendor.

Quote Date: The last time the vendor quoted you a cost.

Quote Exp Date: The date the last quote expires (Adjutant allows a company to use either Last Received Cost or Last Quoted Cost as the default cost on purchase orders).

Rating: The supplier's rating.

Discount: The normal discount you receive from this supplier for this item

Lead Time: The normal lead time (in days) for this item from this supplier. This will be updated according to your system's setup (last # of receipts or last # of days).

MFG Part#: The manufacturer's part number for this item

Customer

Customer: The customer's Organization ID and Name

Customer Part#: The customer's part number for this item

Notes

Item Master Notes Tab |

Notes tab is used to enter notes about the item. These notes will be displayed on purchase orders, quotes, sales orders, and invoices.

Pricing

Item Master - PricingPricing tab displays the item's base cost, list sale price, margin between the two, and all of the pricing rules that are currently applied to it.

Drill down on contracts by double-clicking them in the grid, it will open the contract in the Contract Master.

Fields/Filters

Here is a list of fields and filters from the pricing tab:

- Base Cost

- List Sales Price

- Margin %

- Group/Client

- Item Group

- Unit

- Start Qty

- End Qty

- Amount

- Type

- Orig

- Price

- Margin %

- Start Value

- End Value

Expiring Date

Item Master - Expiring DateExpiration Date tab displays information about the expiration dates of the items received.

Fields/Filters

Here is a list of fields on this tab:

- Exp.Date

- Location

- Qty in Pack

- PackID

- Whse

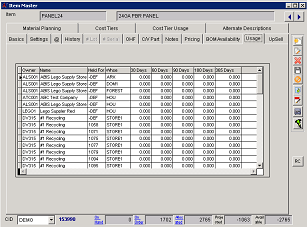

Usage

Item Master Usage Tab |

Usage tab displays the usage of items in 30, 60, 90, 180, and 365 intervals.

Fields/Filters

Here is a list of fields on this tab:

- Quantity

- Ext Price

- Ext Cost

- Avg. Sell Price

- Ext. Profit

- # of Customers

- Owner

- Name

- Held For

- Whse

UpSell

Item Master - UpSellUpSell screen allows you to see what related items have been sold and the number of times they have been sold.

Fields/Filters

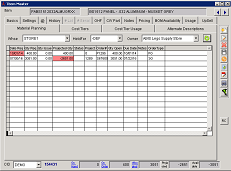

Material Planning

Material Planning system is tightly integrated with the Customer Orders, Inventory, Sales Analysis (Forecasting), Purchasing, and the Manufacturing modules of Adjutant, and is sensitive to company and plant specific criteria. This MP software analyzes the existing stock status of all raw materials and finished goods. With Adjutant’s Material Planning screens you can determine precisely when and how much material should be purchased or manufactured based on a time-phased analysis of sales orders, production orders, purchase orders, current inventory levels and forecasts. This demand analysis can be viewed daily, weekly, or monthly.

Item Master Material Planning Tab |

Fields/Filters

- Date Req

- Qty Req

- Qty Issue

- Projected Qty

- Status

- Project

- Order#

- Qty Open

- Due Date

- Notes